Getting Started with Green Hydrogen!

Vinayak Kathare

April 2023

The objective of this article is to pique your curiosity around Green Hydrogen and understand the basic nomenclature and math behind this technology. There will be little bit of chemistry as well – but don’t get scared, as that’s where the fun lies. This article will not cover any projected demand by type of applications. Tune back to this page a little later for more on that!

APPLICATIONS

Demand for Hydrogen (H2) is not new! Today, almost all the demand comes from the industrial sector, especially fertilizers and refineries. Its potential is huge, which is why future demand though can be broadly categorized across three segments:

- Industries

- Production of Ammonia (NH4)

- Refineries

- Methanol production

- Manufacturing of Steel

- Industrial heat

- Transportation, specifically Fuel Cell Vehicles

- Energy Storage

WHAT IS “GREEN” HYDROGEN?

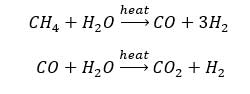

All of today’s Hydrogen is produced by processes that release Green House Gas emissions (GHGs). One such common process is Steam Methane Reforming by using natural gas i.e., Methane as raw material.

This process takes place in two steps to combine natural gas with steam to release H2 and CO2. As evident, Hydrogen is produced but alongside CO2 which is our enemy that causes global warming.

Green Hydrogen, as the name suggests is a term coined for generating H2 in a Climate-friendly manner – by splitting water into Hydrogen and Oxygen in a process known as Electrolysis of water, and 2.by sourcing electricity required for electrolysis from Renewables, making this entire process green & clean. It is to be noted that the production of 1 kilogram of Hydrogen requires 9 litres of water, which results in the release of 8 times the amount of Oxygen.

But why is Green Hydrogen catching so much attention only now? There are two main reasons: Increased focus from governments across the globe as well as the corporate sector to fight climate change and falling prices of renewable power. Despite the increasing popularity of direct electrification, it is widely recognized around the world that Green Hydrogen is a crucial element in the entire range of solutions to achieve long-term sustainability in our power consumption practices.

IS GREEN HYDROGEN ECONOMICAL TODAY?

The short answer is not yet. The cost of commercially produced Hydrogen from the SMR process ranges between $1.8-2.4 per kg, depending upon the cost of natural gas. Comparatively, the cost of producing one kg of Green Hydrogen today is a little more than double at $4-6. For both processes to become cost comparable, it is likely to take a few more years, personally my bet is around 2030.

Here are three drivers that will reduce the cost of Green Hydrogen:

- Cost of Electrolyzers

Cost of alkaline electrolyzers is around ~6.3 Cr/MW today. It is estimated to drop to ~2.8Cr/MW by 2030 due to economies of scale – the caveat is that the production capacity of electrolyzers will have to ramp up to nearly 5GW by the end of the decade (from mere ~0.2 GW today) to achieve the same. - Cost of Renewable Power

In today’s scenario, it takes around 50 kWh of electricity to produce 1 kg of Green Hydrogen. (With electrolyzer efficiency of 70%) Assuming cost of renewable power to be INR 3/kWh – the electricity costs per kg of Green Hydrogen alone becomes INR 150. The cost of renewables will have to drop by at least 33% to make Green Hydrogen commercially feasible. Sourcing Round-the-Clock power from Wind-Solar-Storage hybrid and falling prices of storage will make that happen in the near-term. - Efficiency of Electrolyzers

Efficiency of Alkaline electrolyzers is around 65 to 70% today and it is estimated to increase to 80% by 2030.

COMPETITION TO GREEN HYDROGEN: ‘BLUE HYDROGEN’ & DIRECT ELECTRIFICATION

Green Hydrogen is likely to compete with two other technologies:

- BLUE HYDROGEN:

This is a term used for Hydrogen produced with steam methane reforming – but the CO2 produced in this process is captured and sequestered so as not to release it in atmosphere. Carbon capture and sequestration of course adds to the cost of pure production of Hydrogen with SMR.

From India perspective, we are more dependent upon import for natural gas, which is more expensive. On the other hand, the land is blessed with high resources of renewables: making it is better suited for adoption of Green Hydrogen than Blue hydrogen in the long term.

- DIRECT ELECTRIFICATION:

For applications such as industrial process heat and low distance, low duty transport – direct electrification will make more sense than use of Green Hydrogen and further combustion of Hydrogen in fuel cells.

QUICK SUMMARY OF INDIA’s GREEN HYDROGEN POLICY

The Ministry of Power released a policy document for production of Green Hydrogen and Green Ammonia in February 2022. Some key highlights of this policy are:

- Banked renewable energy considered for production of Green Hydrogen or Green Ammonia

- Waiver of ISTS charges for 25 years for RE projects commissioned before 31st Dec 2030

- Banking of energy permitted for 30 days

- Banking charges to be determined by State Commissions and to be not more than difference between the average tariff of renewable power procured by power distribution company in previous year minus the average market clearing price in day ahead market during the month in which renewable energy is banked

- Priority connectivity for ISTS connected renewable power plants for purpose of Green Hydrogen or Green Ammonia production

- Power Distribution licensee can procure renewable power and supply for Green Hydrogen or Green Ammonia production by adding only Wheeling charges and a small margin (to be determined by respective state Commissions)

- MNRE to set up single portal for all statutory clearances and permissions for manufacturing, transportation, storage, and distribution of Green Hydrogen/Ammonia

- MNRE may aggregate demands to procure Green H2 or Green NH4 through implementing agencies.

ROLE OF FOURTH PARTNER ENERGY

Fourth Partner Energy has Wind-Solar Hybrid/ Co-located power plants coming up in the states of Gujarat, Maharashtra, Karnataka and Tamil Nadu as well large scale ISTS-connected solar and wind power plants. Fourth Partner Energy also has in-house expertise in energy storage solutions.

With these solutions, we are ideally poised to cater to renewable power demands (with or without banking) for Green Hydrogen or Green Ammonia production for our industrial customers. To know more about our customised RE offerings, visit www.fourthpartner.co or reach out to marketing@fourthpartner.co.

(RESEARCH & REFERENCES)

This article can be considered an understanding and super short summarisation of two reports that I found extremely insightful & informative.

- ‘The Potential Role of Hydrogen in India – a pathway for scaling-up low carbon hydrogen across the economy’ by Will Hall, Thomas Spencer, G Renjith, Shruti Dayal, The Energy Research Institute, 2020

- ‘A Green Hydrogen Economy for India’ by Tirtha Biswas, Deepak Yadav, Ashish Guhan Baskar, CEEW and Shakti Sustainable Energy Foundation, Dec 2020.